the technology

PVD (Physical Vapor Deposition) is a coating under controlled vacuum or atmospheric conditions.

This method permits to coat any material in any shapes,achieving metallized effects extremely resistant and durable over the time

the machines : horizontal / vertical

new and refurbished

The main equipment parts are as follows:

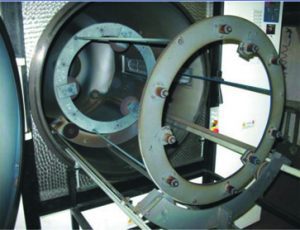

• process chamber

• vacuum pumping group

• electrical power supply system and control of gas flow

• electrical power supply system, control and generation of plasma

• PC and software control to ensure repeatibility of the process

• safety and self-diagnosis system

The process chamber contains the Plasma sources (stainless steel bars, aluminum or titanium)

powered by radio-frequency, mid – frequency or direct current.

The chamber is internally lined with stainless steel protection shields.

It is equipped with portholes for visual checking of the process and it’s thoroughly tested with a

helium mass spectrometer to guarantee its perfect sealing and air tightness in time.

machines

All the plants have automatic process control, temperature detection, pressure and gas flow

regulation, aswell as different substrate supports, including patented rapid loading systems.

Supplied on request: cold/hot water feeding, cleaning plants and instruments for quality control, for

example, Kalo-Tester, Rockwell-Tester, microscope with image elaboration.

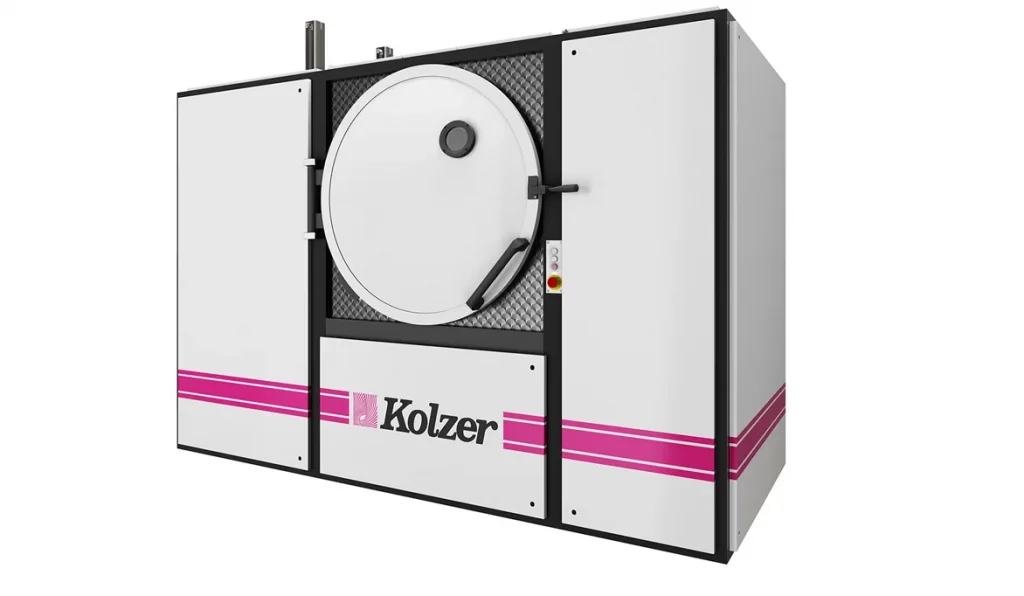

horizontal

KOLZER DGK36”

Volume

ø 1000 mm x 1300 mm

Available technologies:

Sputtering

Thermal Evaporation

Plasma PECVD

Magnetron Sputtering

from 1 to 4

Productivity

from 4 min cycle

KOLZER DGK63”

Volume

ø 1600 mm x 1750 mm

Available technologies

Sputtering

Thermal Evaporation

Plasma PECVD

Magnetron Sputtering

from 1 to 6

Productivity

from 5 min cycle

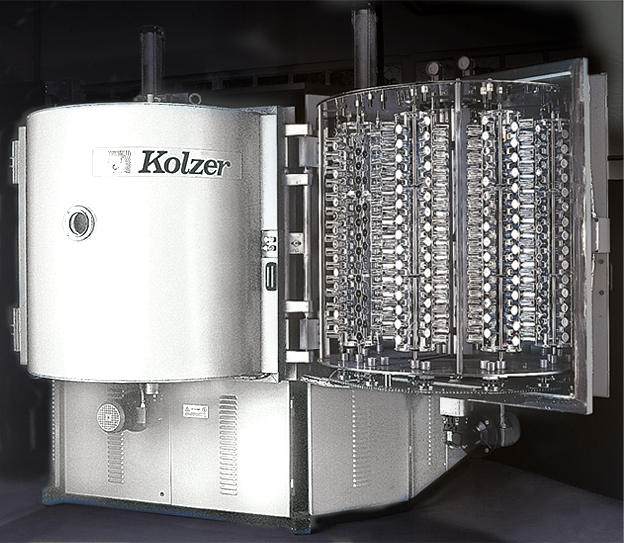

vertical

KOLZER

MK63”

Volume

ø 1600 mm x 1450 mm

Available technologie

Sputtering

Thermal Evaporation

Plasma PECVD

Magnetron Sputtering

from 1 to 6

Productivity

from 5 min cycle